PSE Research Projects

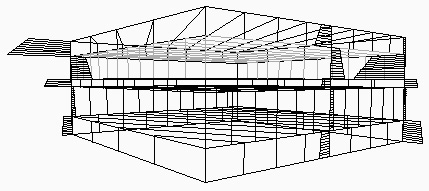

WBCSim is a prototype PSE that is intended to increase the productivity of wood scientists conducting research on wood-based composite materials, by making legacy file-based FORTRAN programs, which solve scientific problems in the wood-based composites domain, widely accessible and easy to use. WBCSim currently provides Internet access to command-line driven simulations developed by the Wood-Based Composites (WBC) Program at Virginia Tech. WBCSim leverages the accessibility of the Web to make the simulations with legacy code available to scientists and engineers away from their laboratories. WBCSim integrates simulation codes with a graphical front end, an optimization tool, and a visualization tool. The system converts output from the simulations to the Virtual Reality Modeling Language (VRML) for visualizing simulation results. WBCSim has two design objectives: (1) to increase the productivity of the WBC research group by improving their software environment, and (2) to serve as a prototype for the design, construction, and evaluation of larger scale PSEs. The simulation codes used as test cases are written in FORTRAN 77 and have limited user interaction. All the data communication is done with specially formatted files, which makes the codes difficult to use. WBCSim hides all this behind a server and allows users to supply the input data graphically, execute the simulation remotely, and view the results in both textual and graphical formats.

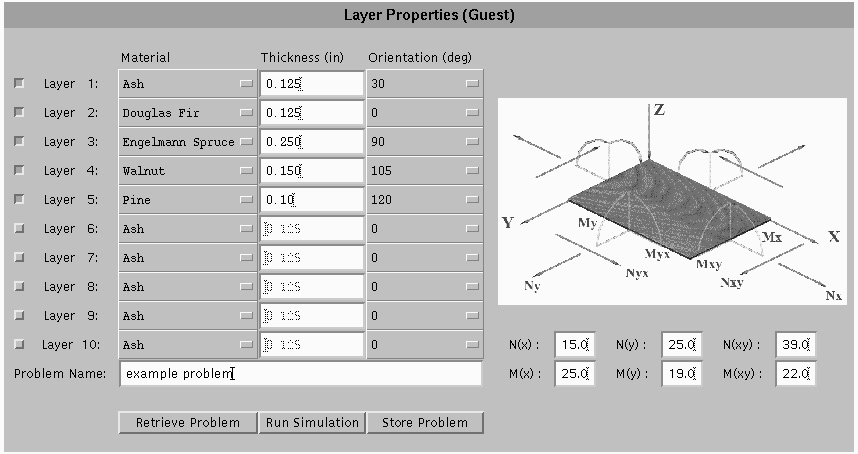

WBCSim contains four simulation models of interest to scientists studying wood-based composite materials manufacturing-rotary dryer simulation (RDS), radio-frequency pressing (RFP), composite material analysis (CMA), and particle mat formation (MAT). The rotary dryer simulation model was developed as a tool to assist in the design of drying systems for wood particles, such as used in the manufacture of particleboard and strandboard products. The rotary dryer is used in about 90 percent of these processes. The radio-frequency pressing model was developed to simulate the consolidation of wood veneer into a laminated composite, where the energy needed for cure of the adhesive is supplied by a high-frequency electric field. The composite material analysis model was developed to assess the strength properties of laminated fiber reinforced materials, such as plywood. The mat formation model is used to calculate material properties of wood composites, modeling the mat formation process as wood flakes are deposited and then compressed into a mat. This model is crucial for all other manufacturing process models, as they require material properties as input.

The software architecture for WBCSim is three-tiered: (i) the legacy simulations and various visualization and optimization tools, perhaps running on remote computers; (ii) the user interface; and (iii) the middleware that coordinates requests from the user to the legacy simulations and tools, and the resulting output. These three tiers are referred to as the developer layer, the client layer, and the server layer, respectively. The developer layer consists primarily of the legacy codes on which WBCSim is based. The server layer expects a program in the developer layer to communicate its data (input and output) in a certain format. Thus, legacy programs are `wrapped' with custom Perl scripts, and each legacy program must have its own wrapper. The client layer consists of Java applets and is responsible for the user interface (see Figure). It also handles communication with the server layer, is the only layer that is visible to end-users, and typically will be the only layer running on the user's local machine. The server layer is the core of WBCSim as a system distinct from its legacy code simulations and associated data viewers. The server layer is responsible for managing execution of the simulations and for communicating with the user interface contained in the client layer. WBCSim applications require sophisticated management of the execution environment; the server layer, written in Java, directs execution of multiple simulations, accepts multiple requests from clients concurrently, and captures and processes messages that signify major milestones in the execution (such as the computation of an intermediate value). Graphical results from the simulations are communicated to the clients using an HTTP server (see Figure).

Last modified: November 5, 2001